- Customized Fit +

- Technology +

- Company +

We are an American health-driven company that firmly believes in nurturing overall well-being from the very basics – the feet.

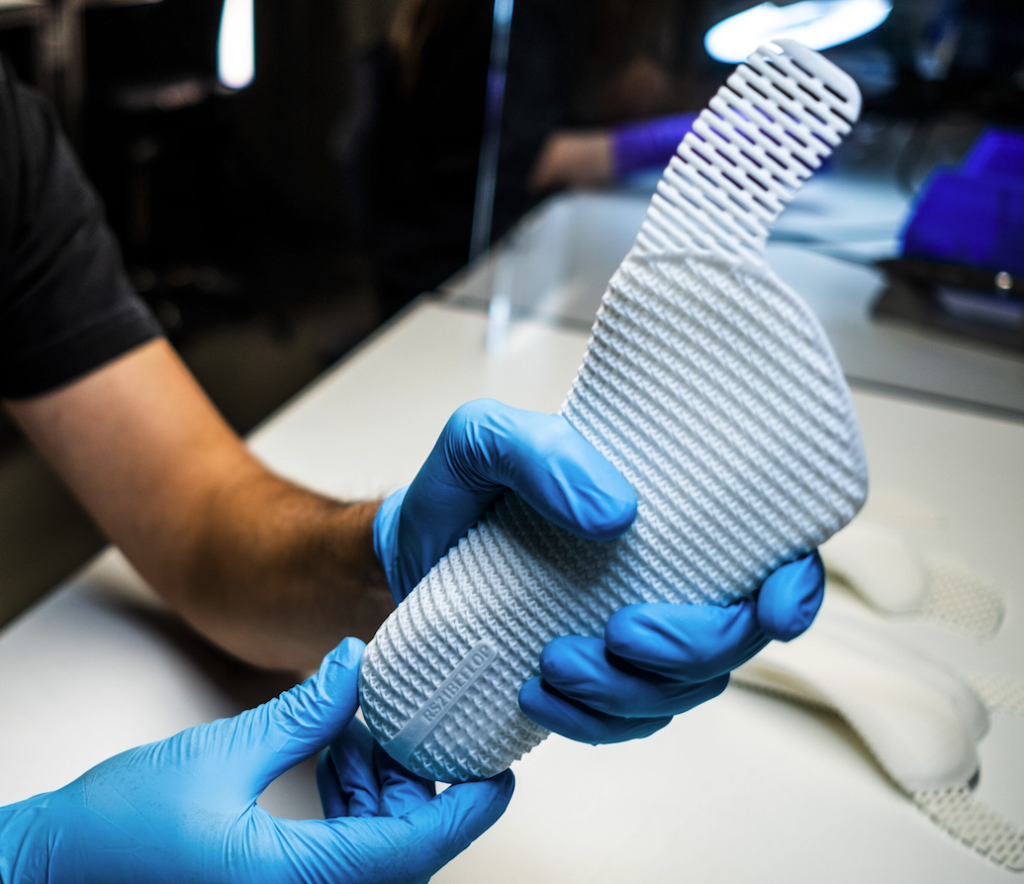

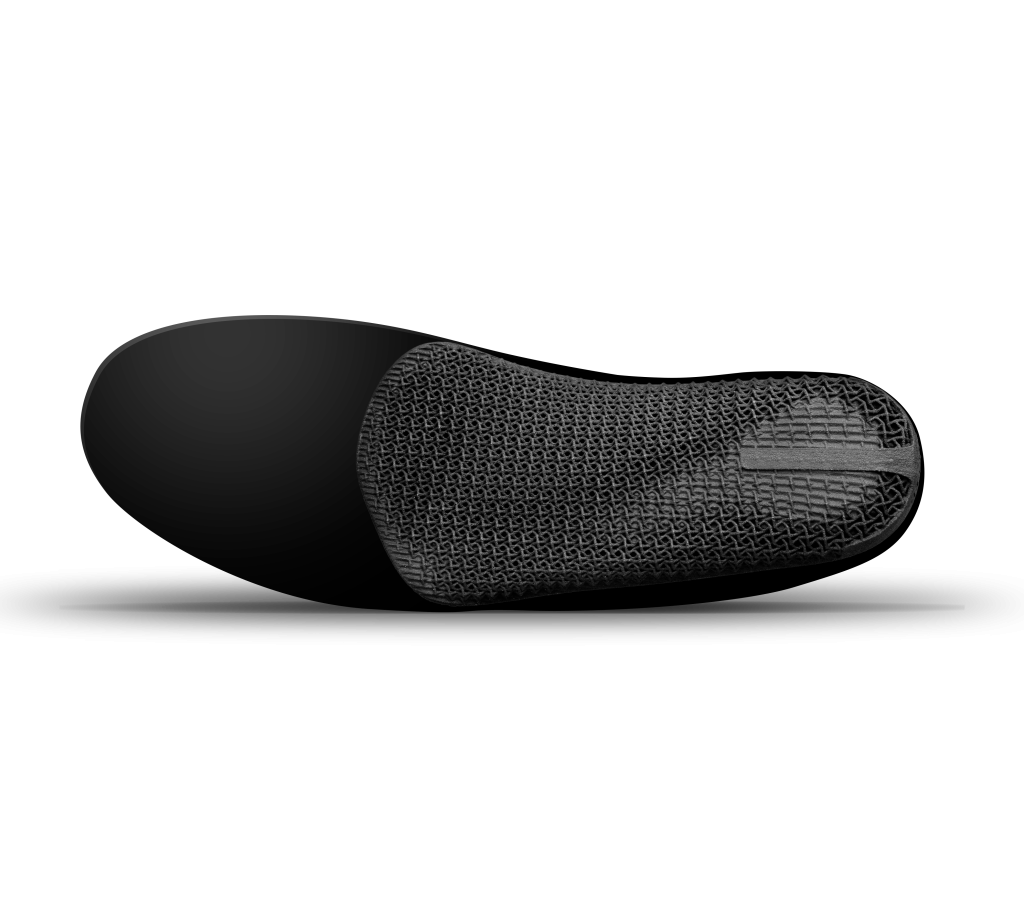

We took this belief to the core of our work and blended innovation, advanced technology and profound expertise to provide our customers with high-tech 3D customized insoles that ensure them with seamless movement, uncompromising comfort and a life free of pain.

We took this belief to the core of our work and blended innovation, advanced technology and profound expertise to provide our customers with high-tech 3D customized insoles that ensure them with seamless movement, uncompromising comfort and a life free of pain.

We are driven to create the most advanced insoles with the finest and most durable materials, providing long-term support and comfort with every step you take.

#PerfectingYourMotion

#AdvancedTechnology

#move

#3DPrinting

But all are agreed as they join the stampede

You should never take more than you give…. .”

(Circle of Life, Elton John)

On top of that the HP Multi Jet 3D printer can accommodate a substantial volume of insoles while minimizing the waste generated, in contrast to the excessive waste associated with traditional CNC polypropylene milling. While traditional CNC waste can be recycled, it requires a high amount of energy, labor, and transportation resources to do so.

Are 3D Printed Insoles The Secret For Happy Life?

Sports Alert – NFL FOX

Overcome foot disorders with a 100% CUSTOMIZED 3D PRINTED INSOLES that will perfect your motion and provide unparalleled support and relief for every step you take.

Stay updated on foot health matters, FeetTech’s most recent innovations, newsletter and special offers.

(786) 314 9094

Hours:

Monday-Saturday

10:00 am – 6:00 pm EST